MEGFIN TAMPING RAMMER MEGFIN Tamping Rammers: A Key to Solid...

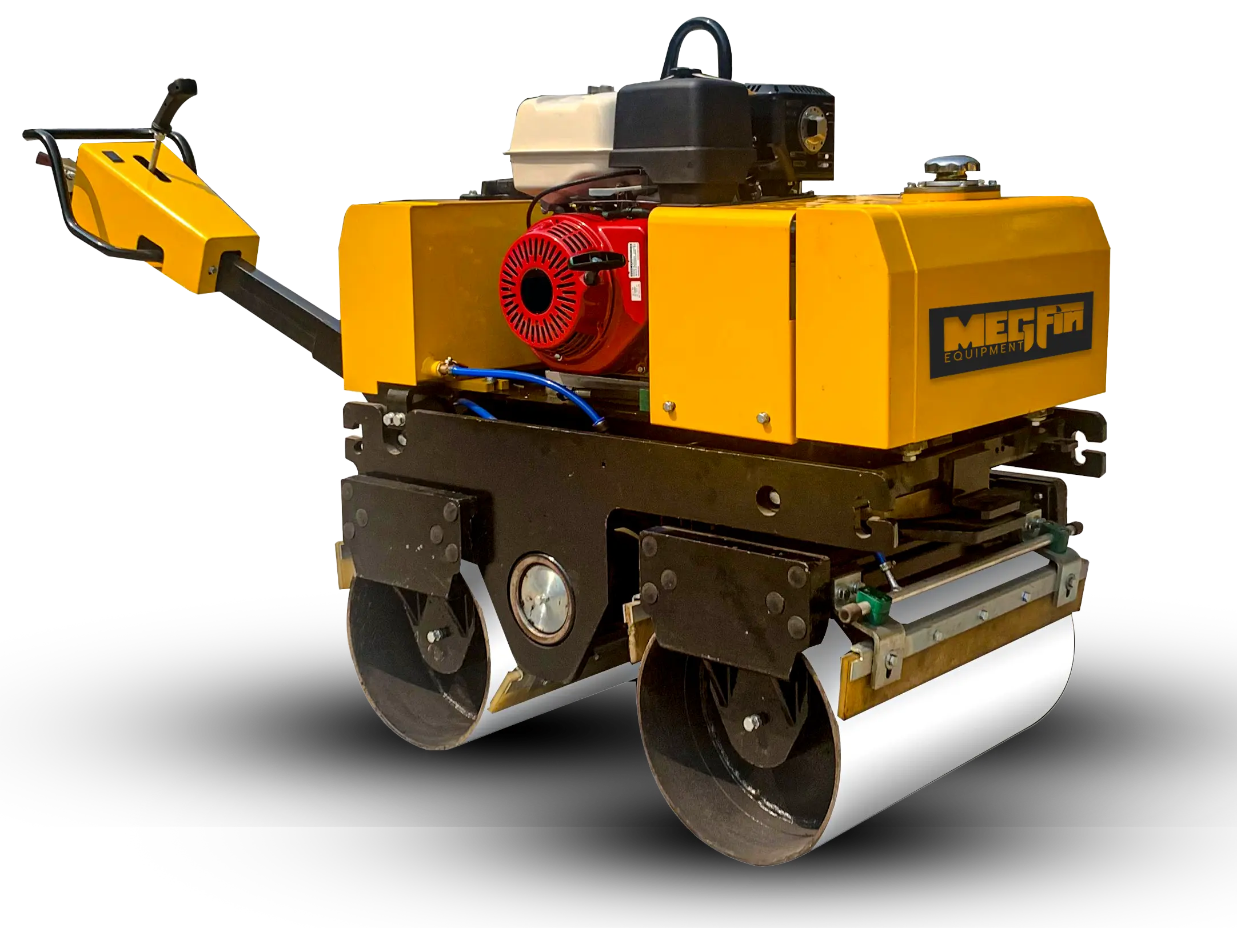

Read MoreMEGFIN ROLLER COMPACTOR

Essential Guide to MEGFIN Roller Compactors: Types, Applications, and Benefits

What Are Roller Compactors?

Roller compactors are heavy machinery used to compact soil and other materials to increase their density. By applying weight and pressure, they help eliminate air pockets and voids, providing a solid foundation for roads, buildings, and other structures.

Compactors work through a combination of static pressure, vibration, and impact, helping ensure that the ground is stable enough to support buildings, roads, and other structures. Roller compactors come in various designs, each suited to different compaction needs.

Types of MEGFIN Roller Compactors

Walk-behind vibratory Roller: A walk-behind vibratory roller is a compact and maneuverable piece of construction equipment used primarily for soil compaction and asphalt work in small to medium-sized areas. These rollers are widely utilized in landscaping, road repair, parking lot maintenance, and various other construction applications where a full-sized roller would be too large or difficult to use. Walk-behind vibratory rollers can operate on tight spaces and inclines, making them ideal for areas where larger rollers cannot reach.

Ride-on vibratory Roller: A ride-on vibratory roller is a larger, more powerful piece of construction equipment primarily used for compaction in road construction, large parking areas, highways, and other large-scale projects. Unlike walk-behind rollers, ride-on vibratory rollers are operated by sitting or standing on the machine, allowing for greater speed, power, and efficiency. The operator drives the roller as it moves over soil, gravel, or asphalt, using its vibratory action and heavy drums to compact the material to the desired density.

Applications of Roller Compactors in Construction

Road and Highway Construction: Roller compactors are essential for paving and repairing roads, providing the necessary compaction for base layers and asphalt surfaces to create smooth, durable roadways.

Site Preparation and Land Development: Roller compactors are used to compress soil and other materials in the early stages of construction projects, creating a stable foundation for buildings, bridges, and other structures.

Airport Runways and Taxiways: The demanding weight of aircraft requires airport runways and taxiways to be compacted to extremely high standards. Roller compactors provide the uniformity and density needed to withstand the pressure of heavy air traffic.

Landfill and Waste Compaction: In landfill sites, roller compactors are used to compress waste materials, helping to optimize space and improve landfill management. Specialized compactors are designed to handle these environments.

Benefits of Using Roller Compactors in Construction

Enhanced Stability and Load-Bearing Capacity: Properly compacted surfaces provide a stable base that can withstand heavy loads, ensuring that structures, roads, and foundations remain durable and resistant to settlement or shifting over time.

Reduced Settling and Erosion: Compaction helps reduce air gaps and voids in soil, which minimizes the potential for settling and erosion. This is essential for long-term stability in areas subject to heavy rains, flooding, or seismic activity.

Improved Surface Quality: For road projects, roller compactors help achieve a smooth, even finish on asphalt surfaces, enhancing drivability and reducing the risk of wear and tear from traffic.

Increased Construction Efficiency: Modern roller compactors are designed for efficiency, allowing operators to achieve high-quality compaction in less time. With features like adjustable settings and vibration modes, construction crews can adapt to different materials and conditions.

Key Tips for Using MEGFIN Roller Compactors Effectively

Set the Correct Speed and Frequency: Most modern roller compactors come with variable speed and vibration settings. Adjusting these based on the material being compacted can enhance compaction efficiency and quality.

Maintain Consistent Passes: Consistent, overlapping passes ensure uniform compaction and prevent weak spots. Overlapping each pass by 10-15% can help achieve consistent density across the entire surface.

Monitor Soil Moisture Levels: Soil compaction is most effective when the soil has an optimal moisture content. If the soil is too dry, compaction will be less effective; if it’s too wet, it may become muddy and difficult to compact.

Regularly Inspect and Maintain Equipment: Keeping the roller compactor in peak condition is essential for performance and safety. Regular inspections and maintenance checks on parts like drums, hydraulics, and tires help avoid breakdowns and maintain compaction quality.

Considerations When Using MEGFIN Roller Compactors

Soil Type: Different soil types require specific roller types for optimal results.

Moisture Content: The moisture level in the soil affects compaction efficiency; it should be neither too dry nor too wet.

Layer Thickness: Compacting in thin layers can lead to better density and stability.

Operator Skill: Proper training for operators is crucial to ensure safe and effective operation.

Conclusion

In summary, MEGFIN roller compactors are essential tools for achieving high-quality compaction in various construction projects. With their different types and applications, they contribute significantly to the stability and longevity of structures. By understanding their functions, benefits, and considerations, construction professionals can make informed decisions to enhance their projects’ effectiveness and efficiency. Whether you’re planning a road construction project or preparing a foundation, incorporating roller compactors can lead to improved outcomes and a solid foundation for future developments.

Visit our MEGFIN equipment section for your Roller Compactor at the ICM Construction Mall.

Read More blogs

Tom Green Lawnmowers

TOM GREEN LAWNMOWERS Tom Green Lawnmowers: Your Guide to a...

Read MoreDiesel Generators

Diesel Generators Power Up: Understanding Diesel Generators In today’s world,...

Read MoreConcrete Mixers

CONCRETE MIXERS Widest Range of Concrete Mixers in West Africa...

Read More